| |

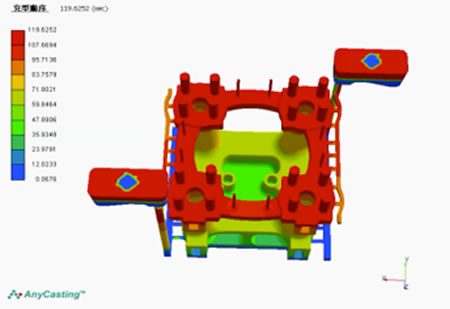

Magmasoft/ Anycasting软件可对充型时间和金属流动速度、金属溶液的温度,凝固时间、宏观及微观缩孔的判定、冷却曲线、铸件及铸型的温度、枝状晶的宏观结构及分布、机械性能、铸件残余应力及变形等进行模拟分析,可查看温度、速度、压力等物理量的分布图,绘制感应器所在位置处的温度、速度、压力的图标,实时的动画显示充型及凝固过程,使用多种判据预测产品收缩,氧化夹渣、卷气缺陷,发热模型对产品收缩产生的影响,过滤网对流动产生的影响,预测浇注和凝固过程中砂芯和砂箱发气导致的困气缺陷,产品的应力分布、变形量及裂纹风险。

technology

Simulation analysis MAGMAsoft / AnyCasting software

can simulate and analyze mold filling time,

metal flow velocity, temperature of metal solution,

solidification time, judgment of macro/micro

shrinkage cavity, cooling curve, temperature of

casting and mold, macro structure and distribution

of dendrite, mechanical properties, residual stress

and deformation of casting. Can view

temperature, velocity The distribution diagram of

physical quantities, such

as pressure, draw the

record of

temperature, speed and pressure at the location of

the sensor, display the filling and solidification

process in real time, use a variety of criteria to

predict product shrinkage, oxidation slag inclusion

and air entrainment defects, the impact of heating

model on product shrinkage, and the impact of filter

screen on flow. Predict

the gas trapping defects caused by the gas

generation of sand core and sand box during pouring

and solidification, and the stress distribution,

deformation and crack risk of the product.

|

|