| |

Taking advantage of software to realize simulation of relevant casting process has enabled casting to improve its operation modes from the old traditional ones into technological casting field and change its effect from invisible to visible, which greatly improves development success ratio of casting, enormously shortens product trial cycle, and optimizes technology plan while at the time avoids the unnecessary costs. In order to improve service level, our Company has introduced two sets of world-class simulation software at large expense; meanwhile simulation analysis on the same product could improve simulation accuracy and provide reliable premise for high-quality casting.

|

|

|

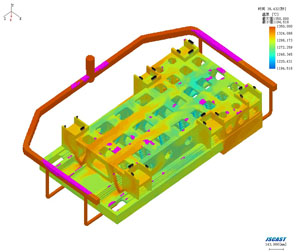

| Fig. 1 |

|

Video I |

Japanese casting simulation software JSCAST could demonstrate the change of parameters during placing and solidifying process, such as temperature, time and the like (as shown in Video I), and predict defects in product molding and solidifying process, like air gap (as shown in Fig. 1), shrinkage cavity, shrinkage porosity and so on, accordingly, optimize technology plan and improve product quality.

|

|

|

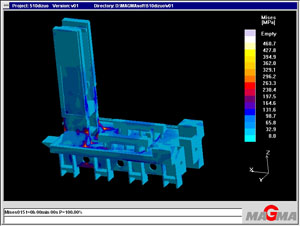

| Fig. 2 |

|

Video II |

German casting simulation software MAGMA could simulate more parameters like thermal center, modulus, metallurgical structure, mechanical property, as well as change of temperature (as shown in Video II) and time, defects like air gap, shrinkage cavity and porosity during placing and solidifying. Moreover, stress analysis model of the software even could simulate stress (as shown in Fig. 2), strain, strain rate, temperature distortion and other relevant parameters of casting during solidifying process; therefore, remedial measures can be taken in stress concentration place in order to eliminate harmful effect and optimize technology plan.

Application of simulation software has enable casting to improve its operation modes from the old traditional ones to technological casting field and to change its effect from invisible to visible, which improves development success ratio of casting, shortens product trial cycle enormously, and optimizes technology plan while at the time avoids the unnecessary costs. Our Company has introduced two sets of world-class simulation software; meanwhile simulation analysis on the same product with two types of software could improve simulation accuracy and provide reliable premise for high-quality casting.

|

|